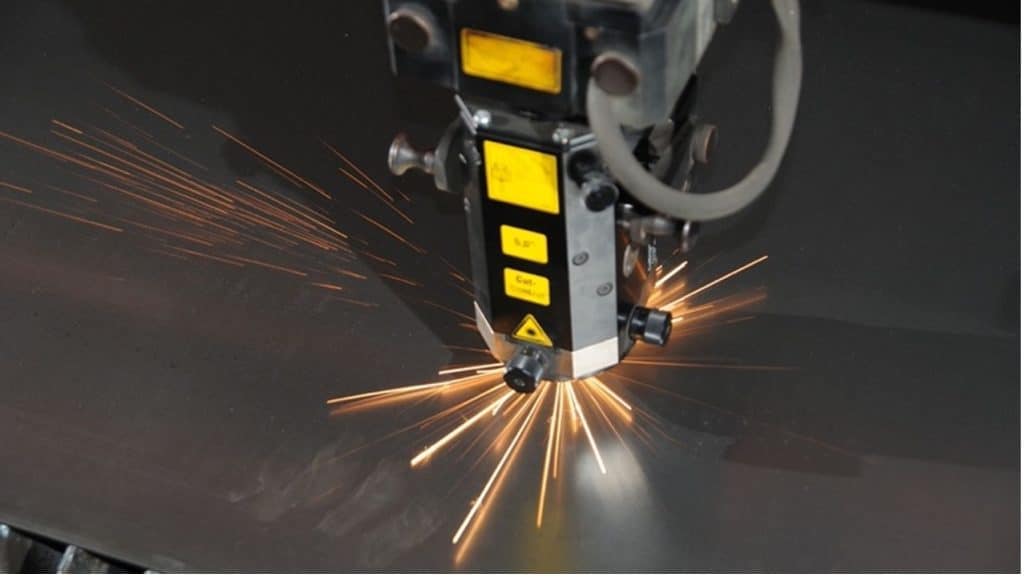

Fibre laser technology is an exciting development in the world of manufacturing. It provides a fast, precise, and efficient way to cut and engrave materials. Unlike traditional cutting methods, fibre lasers use a special type of laser beam that is generated through a fibre optic cable. This technology is becoming increasingly popular among local manufacturers. In this blog, we will explore how fibre lasers work, their various applications, and why Emery Laser is the best choice for high-quality fibre laser cutting services.

Fibre lasers have several advantages over traditional cutting methods:

Fibre laser technology is used in many different industries, showcasing its versatility:

Fibre laser technology is a powerful tool that offers many advantages over traditional cutting methods. Its efficiency, precision, and versatility make it an ideal choice for various applications in different industries. Here at Emery Laser, we are Stainless Steel and aluminium specialists. We leverage the power of fibre laser technology to deliver top-notch cutting and engraving services specifically for these materials.

In summary, understanding the basics of fibre laser technology and its applications can help businesses make informed decisions about adopting this innovative solution. Whether for intricate designs, precise cuts, or complex engravings in Stainless Steel and aluminium, fibre lasers are set to transform how we work with these materials. Choose Emery Laser as your trusted partner for all your fibre laser cutting and engraving needs in stainless steel and aluminium.

Citations:

[1] https://www.semanticscholar.org/paper/11fc4c33f63f024017da7a14fc18a79cc2a1da18

[2] https://www.semanticscholar.org/paper/dfa4b046bcb18729405c20eb9df68506fdf318c3

[3] https://www.semanticscholar.org/paper/c0b87cef5980257a8804bef5a32b0c15adad6ed1

[4] https://www.semanticscholar.org/paper/423eebfb3fe1ae47685c6661693003cc884202ac

[5] https://www.semanticscholar.org/paper/8c160c4a8c073acb181789620614cf3faa66905a