Laser cutting is now a key technology in product design. This method improves creativity, efficiency, and precision in manufacturing. Laser cutting gives designers and manufacturers power. It lets them push boundaries and create new products. These products meet the needs of modern consumers. This blog explores the impact of laser cutting on product design and development. It highlights the benefits and uses of laser cutting in different sectors.

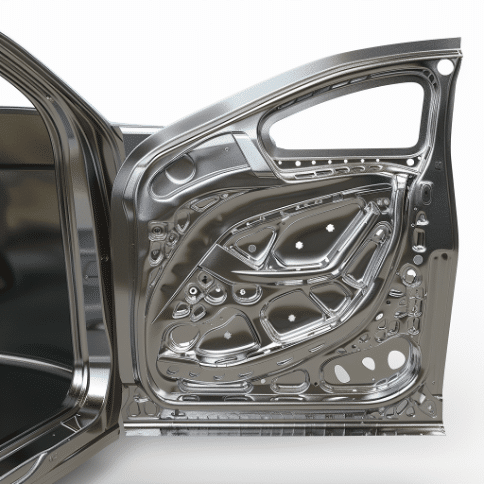

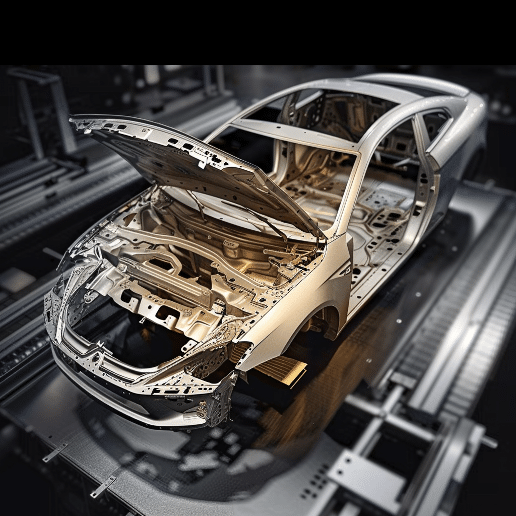

One of the main benefits of laser cutting is its exceptional precision. Laser cutting machines can make intricate designs with tight tolerances. They allow for complex shapes and patterns. These are often hard to achieve with traditional cutting methods. This detail is crucial in industries like automotive and electronics. Components there must fit together seamlessly. This fit ensures the best performance and safety.

For example, the automotive industry uses laser cutting. It is used to make precise parts that meet strict standards. The ability to create detailed designs not only enhances the aesthetic appeal of products but also improves their functionality. Designers can explore new ideas without worrying about the limits of cutting methods.

One of the most significant advantages of laser cutting is its precision. Laser beams can focus on a very small area, allowing for intricate cuts with tight tolerances. This level of accuracy is crucial in the automotive industry, where components must fit together perfectly to ensure safety and performance. Unlike traditional mechanical cutting methods, which can cause material deformation and fraying, laser cutting produces clean edges and high-quality finishes.

Laser cutting methods operate at high speeds, significantly reducing the time needed to complete each cut. This efficiency is particularly beneficial for high-volume production runs, where time savings translate directly into cost savings. The ability to quickly change cutting parameters and switch between different materials also enhances productivity, allowing manufacturers to respond rapidly to changing demands.

Laser cutting technology is versatile and can handle a wide range of materials, including metals, plastics, and composites. In the automotive industry, this versatility allows manufacturers to cut various components, from body panels to intricate interior parts. Additionally, laser cutting can be used for both cutting and welding, streamlining the production process and reducing the need for multiple machines.

Laser cutting is a thermal process that minimizes waste by using material more efficiently. The precision of laser cutting means that manufacturers can nest parts closely together on a sheet, reducing scrap material. This efficiency not only lowers material costs but also contributes to more sustainable manufacturing practices, which are increasingly important in today’s environmentally conscious market.

Several automotive manufacturers have successfully integrated laser cutting into their production processes, reaping the benefits of this advanced technology. A notable case involves an automotive company that faced challenges with traditional cutting methods for synthetic cloth used in their paint shops. This cloth is essential for cleaning car bodies before painting, and it must be lint-free to avoid blemishes in the paintwork. Traditional mechanical cutting methods often resulted in frayed edges, compromising the lint-free quality of the cloth.

By switching to laser cutting, the company achieved clean, sealed edges that eliminated lint and improved the quality of their paintwork. Laser cutting operates through a thermal process that melts and vaporizes the material, producing a semi-sealed cut edge that is free from fraying. This change not only enhanced product quality but also increased productivity and profitability for the company.

For further details, you can refer to the study titled “Enhancing the competitiveness of an SMME in the automotive industry through the introduction of laser based manufacturing,” which illustrates how the introduction of laser cutting into the manufacturing process solved the lint problem and improved overall productivity and profitability. You can find the study here

As technology continues to advance, the future of laser cutting in the automotive industry looks promising. Here are some trends to watch:

As technology continues to advance, the future of laser cutting in the automotive industry looks promising. Here are some trends to watch:

Laser cutting methods are revolutionizing the automotive industry by providing manufacturers with the precision, speed, and versatility needed to meet modern production demands. The advantages of laser cutting—such as improved quality, reduced waste, and enhanced efficiency—make it a vital tool for automotive manufacturers looking to stay competitive in a rapidly evolving market. As technology continues to advance, laser cutting will play an even more significant role in shaping the future of automotive manufacturing, paving the way for innovative designs and sustainable practices. Embracing this technology will enable manufacturers to enhance their production processes and deliver high-quality vehicles that meet the expectations of today’s consumers.

Citations:

[1] https://www.semanticscholar.org/paper/ad7bbca55a27cf7816ffcf060ae62f7d79e349ca

[2] https://www.semanticscholar.org/paper/29b20e0e262303b8eec282c17b0c993b1c32cd06

[3] https://www.semanticscholar.org/paper/74e6eb9501c37402279cd04c2223571bdf9edee7

[4] https://www.semanticscholar.org/paper/77b891d6105f70ea3042f229ea43a4542e12aa61

[5] https://www.semanticscholar.org/paper/11fc4c33f63f024017da7a14fc18a79cc2a1da18