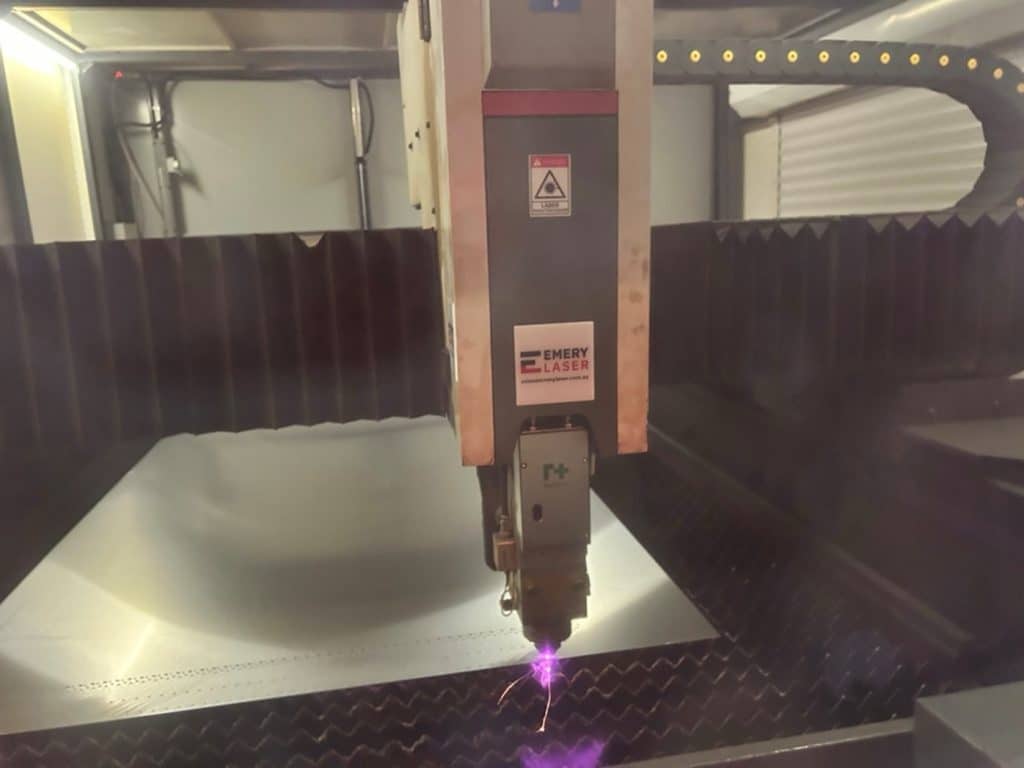

At Emery Laser, we know that laser cutting is a powerful tool for creating precise metal parts, but there are still many myths about how it works. Let’s clear up some of the most common misconceptions, using facts from academic research, so you can make informed choices for your next project.

Many people think laser cutting can only handle thin sheets of metal. In reality, modern fibre laser machines can cut a wide range of thicknesses, including thick stainless steel and aluminium plates. The key is using the right laser power and settings for each job. Research shows that fibre lasers can cut materials up to 25 mm thick with high accuracy and clean edges.

Some believe that laser cutting leaves burnt or jagged edges. This might have been true with older technology, but today’s CNC-controlled fibre lasers produce smooth, burr-free edges. The heat-affected zone (the area changed by the laser’s heat) is very small, which means less warping and cleaner cuts. This is especially important for parts that need to fit together perfectly.

Another myth is that laser cutting is a slow process. In fact, fibre lasers are known for their speed and efficiency. They can cut complex shapes much faster than traditional methods like sawing or punching. Studies have shown that fibre lasers can process materials at speeds up to 10 times faster than CO₂ lasers, especially for thin metals. This means quicker turnaround times for your projects.

Some people worry that laser cutting is too costly for their needs. While the initial investment in laser machines is high, the process itself is very efficient. Laser cutting reduces material waste, minimises the need for extra finishing, and allows for precise nesting of parts, which saves money in the long run. For both small and large production runs, laser cutting is often more cost-effective than other methods.

It’s a common belief that laser cutting is only good for basic shapes. In truth, laser cutting is perfect for intricate designs and detailed patterns. The precision of CNC-controlled fibre lasers means we can create complex parts with tight tolerances, whether you need one custom piece or thousands of identical components.

At Emery Laser, we use advanced fibre laser technology and engineering expertise to deliver fast, accurate, and reliable results for stainless steel and aluminium fabrication. Whether you need custom components or large production runs, our team is here to help you bring your designs to life.

If you have more questions or want to see how laser cutting can work for your business, get in touch with us today for a quote.

References:

Powell, J. (2017). CO₂ Laser Cutting. Springer.

Steen, W. M., & Mazumder, J. (2010). Laser Material Processing (4th ed.). Springer.

Ion, J. C. (2005). Laser Processing of Engineering Materials: Principles, Procedure and Industrial Application. Elsevier.