In the ever-evolving world of metal fabrication, innovation drives efficiency, accuracy, and design possibilities. One technology that is transforming product design for Australian manufacturers is tube laser cutting. At Emery Laser, we have seen first-hand how this cutting-edge process makes new things possible for clients across industries.

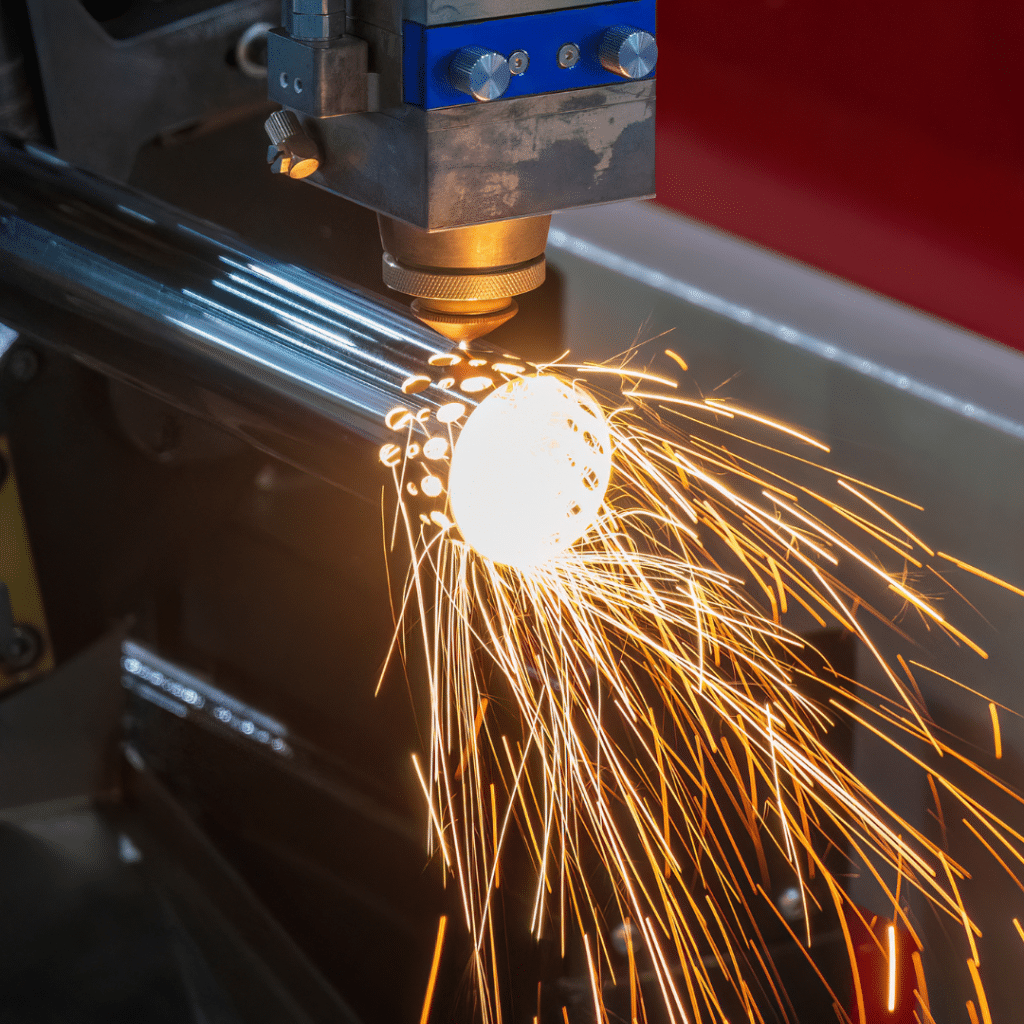

Tube laser cutting uses powerful, focused beams of light (fibre lasers) to cut, etch, and shape metal tubes and pipes. Unlike manual cutting or traditional machinery, laser cutting is computer-driven. Engineers upload detailed mechanical drawings, which are then followed with incredible precision by the laser machine. This results in intricate, repeatable cuts down to fractions of a millimetre.

Before tube laser cutting, designers had to work within the limits of old-school sawing, drilling, and punching methods. These techniques were often slow, required multiple steps, and couldn’t easily handle complex or angled shapes. Now, with laser precision, engineers are free to plan more ambitious and functional products.

For example, it’s far easier to create:

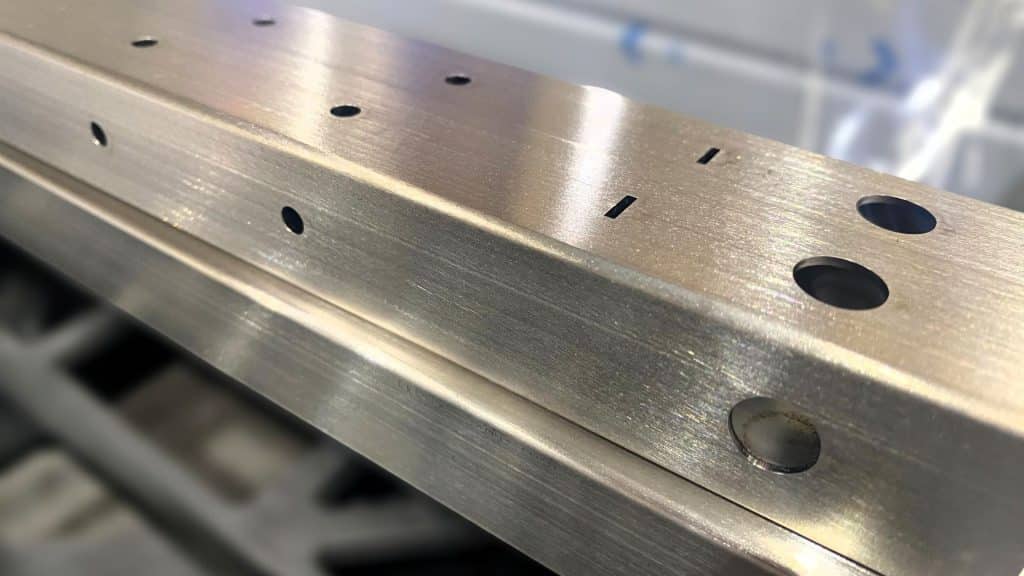

This accuracy enables lighter, stronger, and more efficient designs—a trend backed by research showing that digital production methods like laser cutting support both innovation and higher manufacturing standards (Kumar et al., 2017).

Speed is another key advantage. Because tube laser cutters work directly from a digital file, they reduce setup times and eliminate the need for physical templates. At Emery Laser, jobs that might have taken hours (or days) with manual labour, now run automatically and finish faster. This reduction in labour time and error ultimately lowers manufacturing costs (Alrashdan et al., 2021).

Furthermore, laser cutting maximises material efficiency. The software can nest parts closely together, producing less scrap metal and reducing both costs and environmental impact—an important consideration for Australian manufacturers striving for sustainability.

Another major benefit is consistency. Every cut is precise, every time, regardless of the complexity of the design. This is critical for industries where safety and reliability are paramount, such as construction, transport, and mining. Studies report that laser cutting yields better edge quality and dimensional accuracy compared to traditional methods (Singh et al., 2019).

For manufacturers in Australia, embracing tube laser cutting means being more competitive locally and globally. The ability to turn intricate designs into reality—quickly, accurately, and affordably—helps businesses upgrade their products and stand out in the market.

At Emery Laser, our high-precision fibre lasers empower our clients to push the boundaries of design, ensuring their projects aren’t held back by yesterday’s limitations.

Explore what precise tube laser cutting can do for your next project—contact Emery Laser today!

References