Prototyping metal enclosures is a crucial step for manufacturers on the Gold Coast, Brisbane, and Tweed Shire aiming to bring new products to life. Whether it’s tech casings, industrial control boxes, or custom cabinets, the prototyping process faces several technical challenges. Drawing upon recent academic research and industry experience, let’s explore the most common issues and how advanced solutions improve outcomes for fabrication businesses.

One of the most frequent problems is design oversights—inaccurate drawings, missed cutouts, or inappropriate tolerances. These errors often stem from poor communication between design and production teams. Academic studies highlight that close collaboration and digital sharing of CAD data throughout the prototyping stage dramatically cut design errors and rework time1.

Working with a fabricator who reviews your mechanical drawings and offers digital simulation can validate your design before cutting begins. Modern computer-assisted prototyping ensures alignment between your intent and the manufactured result2.

Choosing unsuitable metal—like using mild steel instead of stainless where corrosion resistance matters—may result in premature product failure or regulatory issues. Research confirms that the prototyping phase is the best time to evaluate a range of materials’ properties (strength, corrosion, weight), preventing costly mistakes in production3.

Request material samples for preliminary tests and consult with your fabricator about the performance requirements in your enclosure’s application. A fabricator experienced in a variety of metals can recommend the optimal option tailored for durability, finish, and compliance.

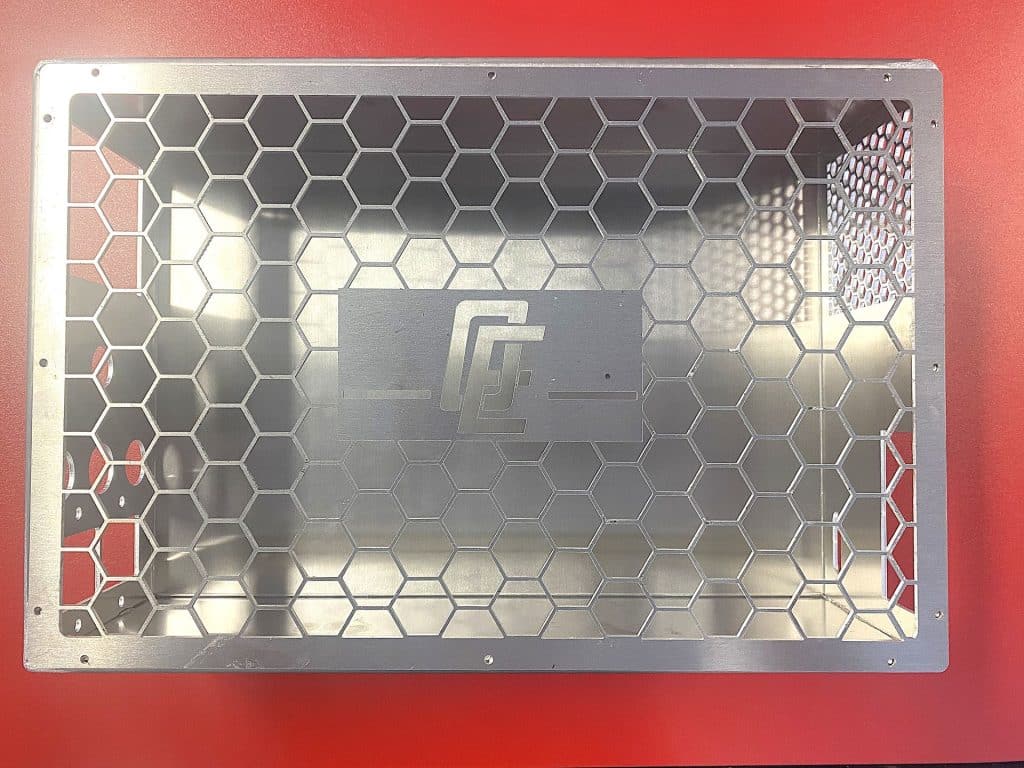

Manual techniques often lead to inaccuracies—holes not lining up, bends out of specification, and inconsistent fit. Advanced rapid prototyping, including fibre laser cutting and CNC folding, brings micron-level accuracy and repeatability, as supported by academic reviews of hybrid manufacturing1.

Opt for digital manufacturing processes like laser cutting, which allow intricate, highly repeatable cuts directly from digital files. This reduces assembly issues and ensures prototypes can be rapidly iterated and improved.

Sharp edges, burrs, and rough surfaces aren’t just an aesthetic problem—they can be safety hazards and complicate final assembly. Research highlights that smooth, burr-free finishes are essential for user safety and product reliability, especially in electronics or industrial controls4.

Use a fabricator that performs post-cut deburring and finishing. Technologies like laser cutting inherently produce cleaner edges, and additional finishing steps can ensure all parts are safe to handle and ready for finishing (such as powder coating).

Improper selection or placement of fasteners during prototyping can cause significant assembly issues in full production. Academic literature emphasises the need for early validation of fastening solutions to guarantee mechanical strength and assembly efficiency15.

Modern self-clinching fastener technology, installed during prototyping, delivers strong, reliable mounting points and reduces issues in later assembly. Work with a fabricator who can install and test fasteners in the prototype, allowing for early verification.

Academic research and real-world results demonstrate that integrating digital manufacturing, careful material selection, and expert finishing dramatically improves prototyping of metal enclosures, cutting costs and lead times while delivering better products134.

At Emery Laser, we use fibre laser precision, expert engineering review, and full finishing services to help local manufacturers overcome these challenges—so you can get from idea to market without costly setbacks.

References

Academic References: