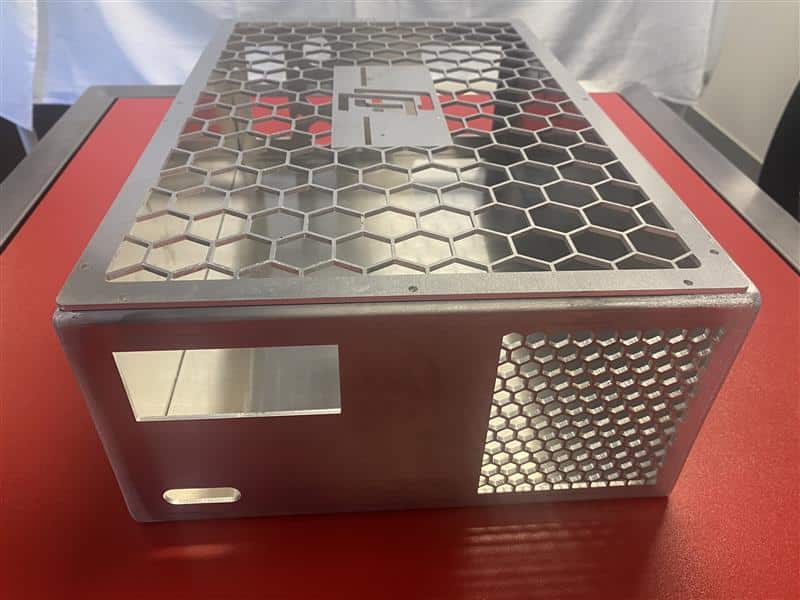

Case Study: Offroad Electrical’s Prototype Electrical Box

Introduction

Offroad Electrical is a specialist brand providing premium electrical systems for off-road vehicles, 4x4s, caravans, and RVs. Known for innovation and reliability, the company identified the need for a new prototype electrical box designed to withstand the punishing conditions of off-road travel.

To bring this idea to life, they needed more than just a fabricator — they needed a partner with prototyping expertise, precision manufacturing, and the ability to deliver quickly without compromising quality.

The Challenge

The prototype presented unique challenges:

- Harsh Conditions: The enclosure had to resist constant vibrations, dust, and the extreme Australian climate.

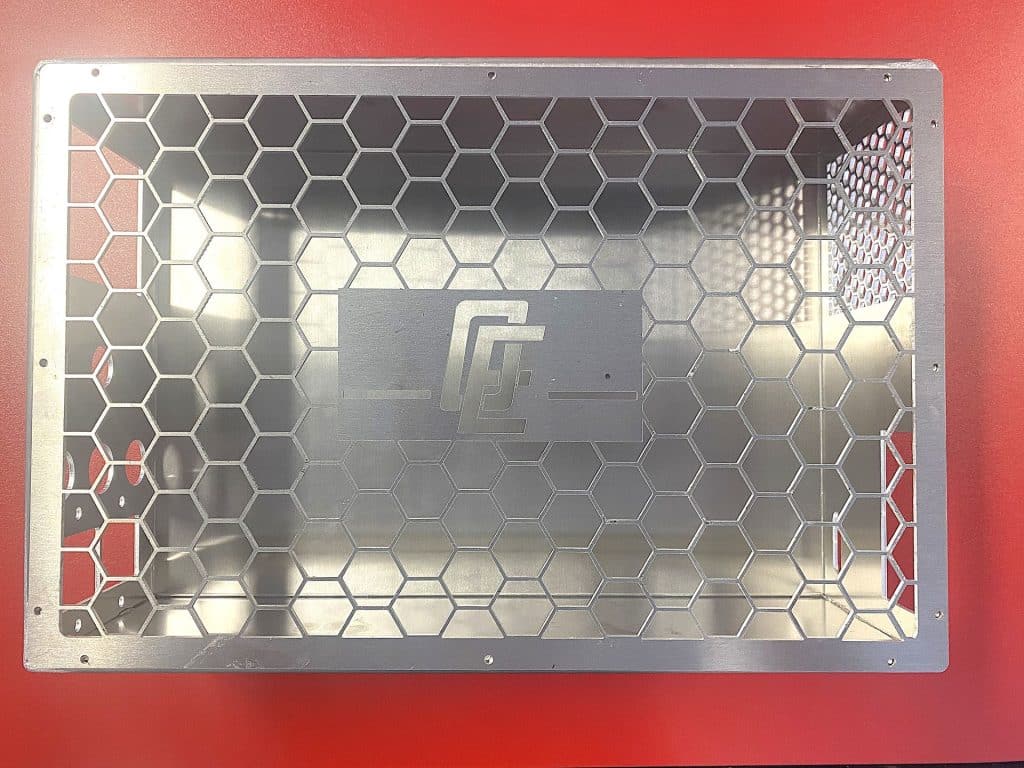

- Precision: Offroad Electrical had detailed technical drawings prepared by a trusted third-party designer. These required exact interpretation to ensure the finished prototype matched the intended design.

- Speed: A quick turnaround was essential to begin product testing and validation.

- Quality Standards: The prototype needed to reflect production-level quality to instill confidence for full-scale manufacturing.

Although the vision and drawings were clear, Offroad Electrical lacked the in-house metal fabrication capabilities to execute the design.

The Solution – Partnering with Emery Laser

After searching for a capable partner, Offroad Electrical connected with Emery Laser, a Gold Coast–based fabrication company with a reputation for excellence in laser cutting, prototyping, and advanced metalwork.

From the outset, it was clear Emery Laser was the right choice:

- Prototyping Expertise: Their team quickly understood the third-party drawings and the intricate requirements of the electrical box.

- Advanced Technology: Precision laser cutting ensured every component matched the exact specifications, while skilled folding and welding produced a seamless, durable enclosure.

- Quick Turnaround: Emery Laser’s streamlined processes allowed Offroad Electrical to move from concept to physical prototype in a short timeframe.

- Industry Understanding: With insight into the off-road and RV market, Emery Laser understood the importance of durability, usability, and finish quality.

The Outcome

The collaboration was a resounding success. Emery Laser delivered a robust, high-quality prototype that not only met but exceeded expectations.

- The prototype’s finish and structural integrityvalidated the third-party design against the demands of off-road use.

- Delivery on time meant Offroad Electrical could advance testing and move toward production without delay.

- Emery Laser demonstrated scalability, proving they could support future full-scale production runs.

Conclusion

This case study demonstrates the value of choosing the right fabrication partner. By collaborating with Emery Laser, Offroad Electrical turned detailed drawings into a production-ready prototype—one that reflects the brand’s commitment to quality and durability in off-road applications.

For Offroad Electrical, Emery Laser was not just a service provider but a strategic partner, enabling innovation, speed, and confidence in bringing a rugged new product to market.