Integrating advanced software into the process of cutting with a laser has redefined what is possible for manufacturers seeking precision and efficiency. Tools like SolidWorks and Nesting Software are not merely digital aids—they are operational assets that elevate every stage of laser-driven production from design through to material utilisation and final output.

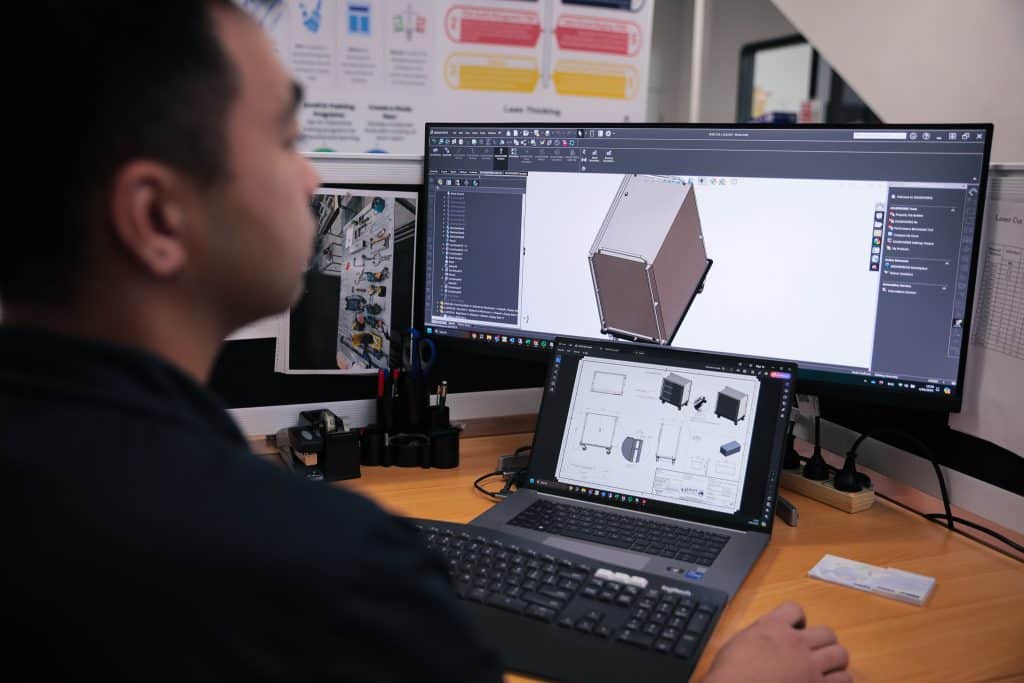

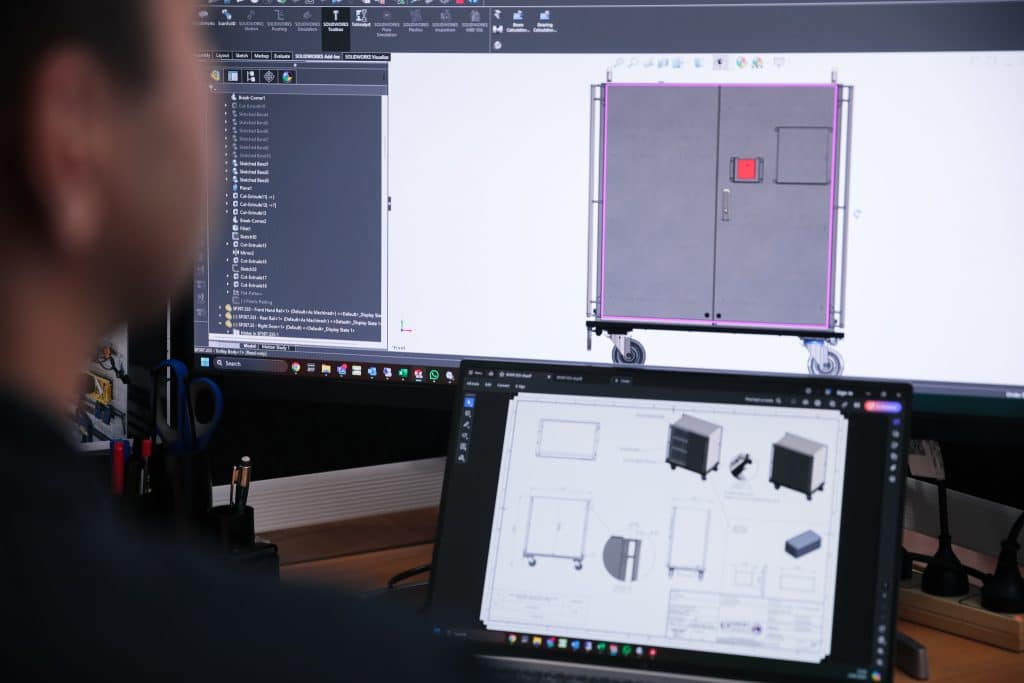

SolidWorks is a leading 3D CAD platform that empowers manufacturing teams to design highly detailed and accurate component models destined for cutting with a laser. This digital workflow minimises miscommunication, eliminates costly manual redrawing, and ensures the geometry produced by the laser cutter aligns perfectly with the original engineering intent. Design files created in SolidWorks can be seamlessly exported into formats compatible with most laser systems, supporting transparent design reviews and revision control at every step.pmc.ncbi.nlm.nih+1

Modern Nesting Software is integral to cost-competitive and sustainable manufacturing. When preparing jobs for cutting with a laser, nesting algorithms automatically arrange part geometries across raw sheet metal to minimise offcut and maximise yield. This approach not only reduces material costs but also supports lean manufacturing initiatives by minimising waste, enabling manufacturers to deliver value without excess resource consumption. matec-conferences

By automating the transfer of digital designs to the shop floor, software removes significant bottlenecks in traditional workflows. When cutting with a laser, the synergy between CAD modelling and nesting eliminates manual data input and ensures production files direct the laser with millimetre precision. The result is consistent, repeatable output, even for complex or high-volume orders, with reduced human error and shorter lead times—key factors in today’s competitive marketplace. pmc.ncbi.nlm.nih

Adopting software-driven processes for cutting with a laser delivers tangible benefits: accurate material estimation, consistent quality control, and confident job scheduling. With real-time design visualisation and simulation, potential issues are resolved before they reach production, streamlining projects from prototyping to large-scale manufacturing.matec-conferences+1

At Emery Laser, our ISO-certified operations on the Gold Coast leverage the full potential of SolidWorks and Nesting Software to optimise every laser cutting job. Our approach ensures Australian manufacturers benefit from tight tolerances, efficient use of materials, and timely delivery backed by rigorous quality assurance.

The adoption of SolidWorks and Nesting Software has fundamentally raised the bar for cutting with a laser in manufacturing settings. These digital innovations offer superior design accuracy, higher material efficiency, and accelerated project delivery, empowering manufacturers to address modern demands for quality and responsiveness. As the industry continues to evolve, software-driven laser cutting stands out as an essential capability for forward-thinking businesses.pmc.ncbi.nlm.nih+1